One of The Reasons Textile Industry Prosperous In China

Air-jet looms are one of the highly air demanding machines in textile industry(An air-jet loom is a shuttleless loom that uses a jet of air to propel the weft yarn through the warp shed. It is one of two types of fluid-jet looms, the other being a water-jet loom, which was developed previously.), texturing machines or cutting, conveying machines are widely use as well.

2 points need to notice when you choose your air compressor plan:

1.All requirements for air compressors’application in textile equipment must be fulfill. Air-jet looms use the biggest amount of compressed air in the industry, the quality of compressed air counts.

2.Ensuring the quality of compressed air can not only making sure the weft yarn through the warp shed steady, but also let the air compressor operate stably and have a clean & tidy environment.

Relevant specification of compressed air for reference:

No liquid water, try to avoid water vapor, dew point less than 8℃;

No oil and dry compressed air;

Remove dust or carbon particles more than 0.1μ;

Air flow tubes need to be carefully calculating as the big demand in compressed air consumption equipment will cause pressure lost or air volume lost.

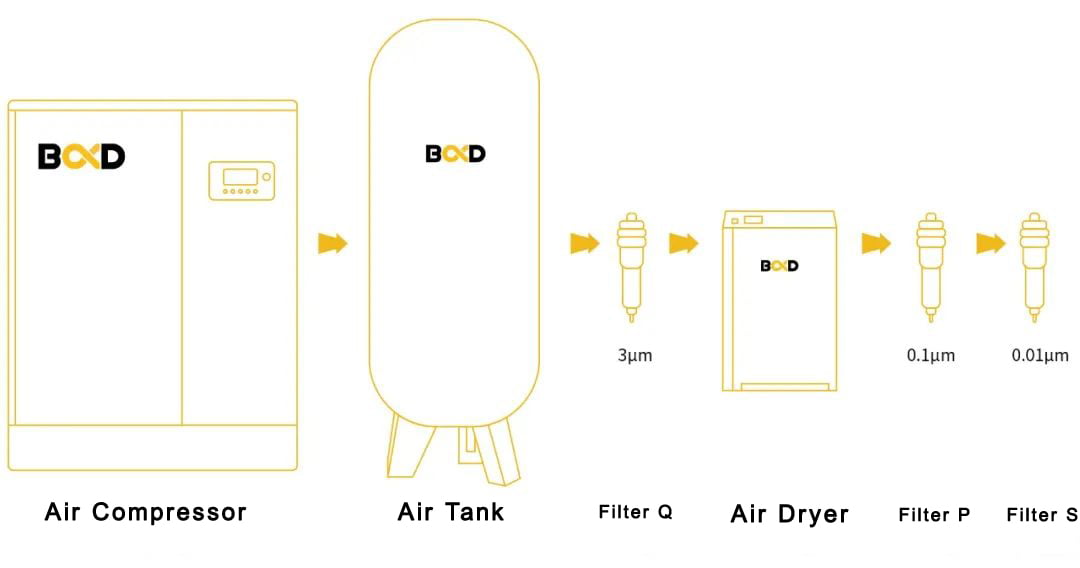

Compressed Air Plan from B&D Air compressor as below